Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. However, it’s crucial to optimize injection mold production to ensure cost-effectiveness without compromising on quality. In this blog post, we will share seven valuable tips to help you achieve cost-effective injection mold production.

- Design for Manufacturing (DFM):

One of the most critical aspects of cost-effective injection mold production is designing the part with manufacturing in mind. Collaborate closely with our design and engineering teams to create a design that minimizes complexity and eliminates unnecessary features. Simplifying the part design reduces the number of tooling components required and shortens the overall production cycle.

- Material Selection:

Carefully choosing the appropriate material for your injection molded parts can significantly impact cost-effectiveness. Consider factors such as the required mechanical properties, part functionality, and expected production volume. Opting for readily available, widely used materials can reduce costs by eliminating the need for special formulations or custom resin orders.

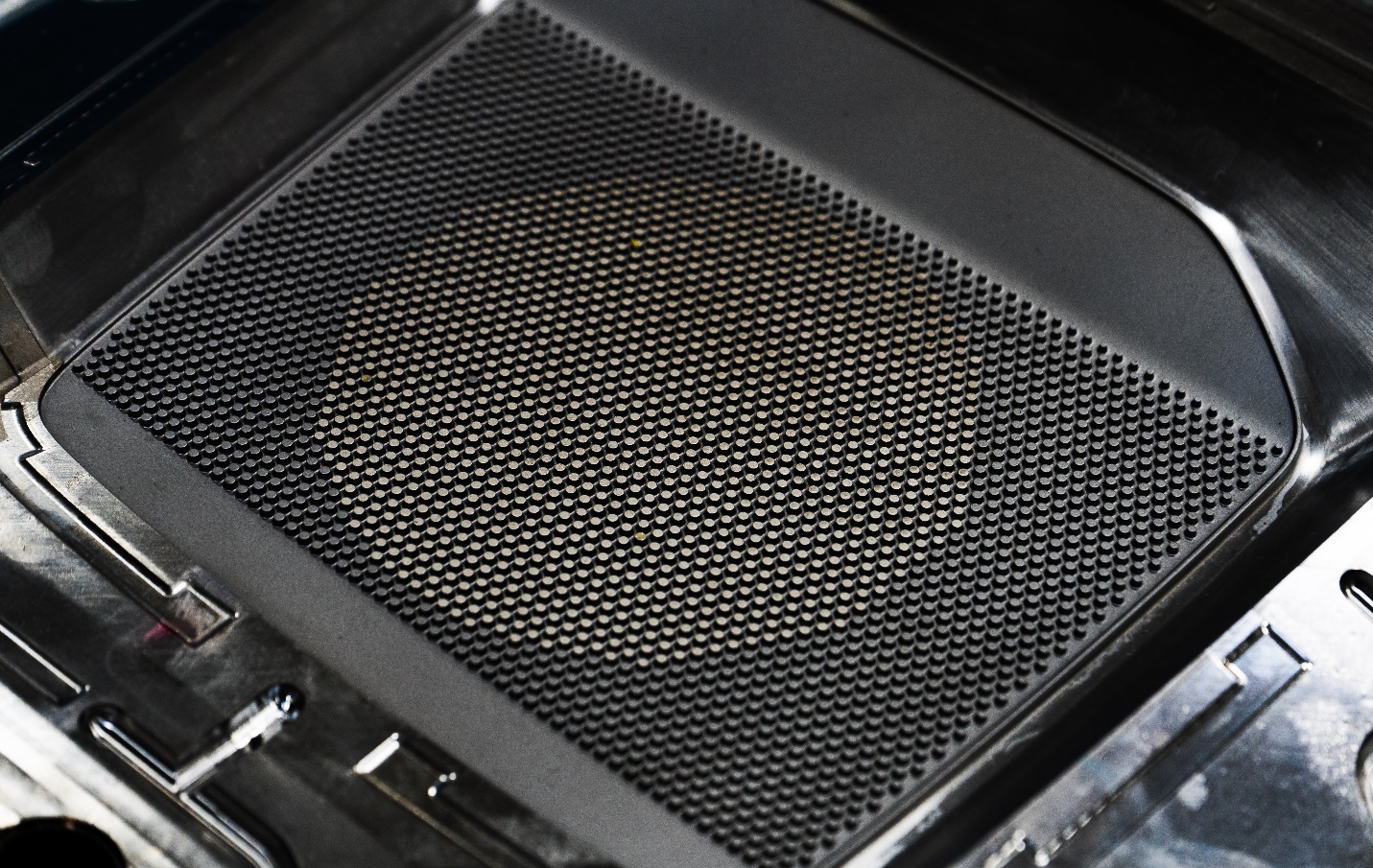

- Mold Material and Construction:

The choice of mold material and construction can greatly affect both production costs and part quality. Selecting the right mold material, such as hardened steel, can ensure longevity and reduce maintenance expenses. Additionally, consider using aluminum or other less expensive materials for low-volume production or prototyping to save costs without compromising on quality.

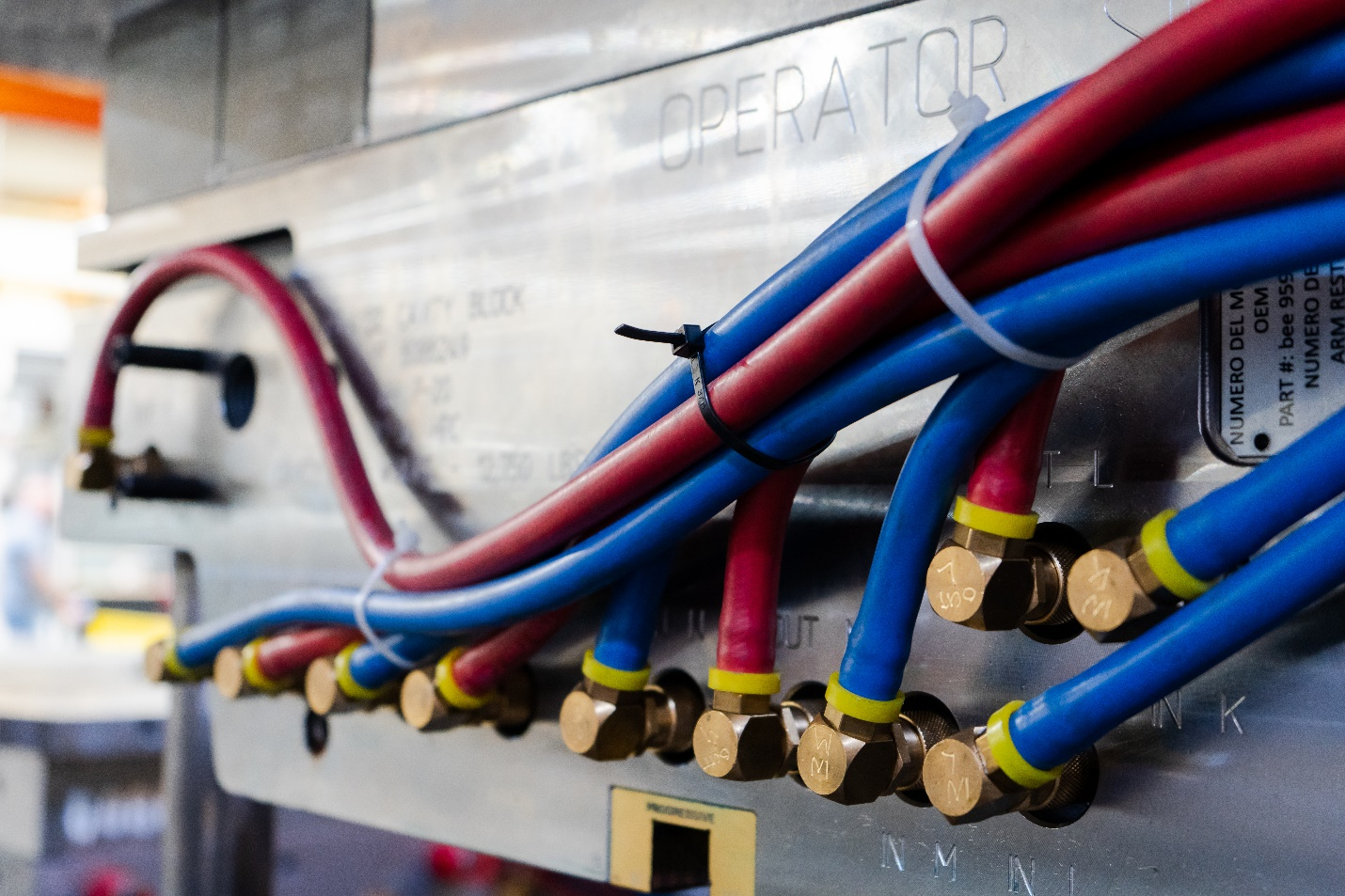

- Optimize Tooling:

Proper tooling design and optimization are crucial for cost-effective injection mold production. Minimize the number of cavities and use multi-cavity molds whenever feasible. Efficient cooling channel designs, such as conformal cooling, can reduce cycle times and increase productivity. Work closely with experienced tooling engineers to ensure optimal design and functionality while minimizing costs.

- Process Optimization:

Streamlining the injection molding process is vital to cost-effectiveness. Optimize process parameters, such as injection speed, pressure, and temperature, to minimize cycle times without compromising part quality. Implement automated or robotic systems for material handling and part ejection to improve efficiency. Conduct regular maintenance and troubleshooting to prevent unexpected downtime and reduce repair costs.

- Consider Hybrid Molding:

In certain cases, utilizing hybrid molding techniques can help achieve cost-effective production. Hybrid molding combines multiple manufacturing processes, such as overmolding or insert molding, to produce complex parts with reduced tooling requirements. This approach can save costs by eliminating the need for separate molds or post-molding assembly steps.

- Collaborate with Injection Molding Experts:

Circle 5’s experienced injection molding experts can offer invaluable insights for cost-effective production. Our team of professionals have in-depth knowledge of the process, materials, and tooling techniques. They can guide you throughout the production cycle, from design optimization to material selection, ensuring efficient and cost-effective mold production.

Cost-effective injection mold production requires careful consideration of various factors, including design, materials, tooling, and process optimization. By following the tips discussed in this blog post and collaborating with our team of experts, you can achieve significant cost savings while maintaining high-quality standards. Emphasize simplicity, efficiency, and optimization throughout the entire production process to maximize your returns and stay competitive in the market.