Kim Thiara (Chair) and Saylo Lam (Vice-Chair) of the Canadian Association of Moldmakers who will be providing an inside look at the moldmaking industry in Canada, how the industry is evolving, and the employment opportunities available.

The times, they are a changin’Manufacturing is a cornerstone of Canada’s and Ontario’s prosperity. That prosperity is what made people from around the world want to call this region their home. Making things here has given us a global reputation for advanced manufacturing that provides innovative products, processes, and solutions…

Mold making is a critical component of many manufacturing processes, from the mobility and aerospace industries to consumer goods and medical devices. As technology continues to evolve, so too will mold making. Here are some key innovations and trends to watch for : The rise in additive manufacturing options, such…

As we wrap up the year, it’s important to make time to reflect on where you started and finished the year. As a learning company, we at Circle 5 set goals for ourselves both individually and organization-wide. This year we focused on three key learning areas: Connectivity, Discovery, and Challenge.…

I originally wanted to be a mechanic, so I took about 3 years of that in high school. It was one of my teachers who introduced me to manufacturing. He told me “You don’t want to be a mechanic because you’ll be fixing other people’s problems. If you go into…

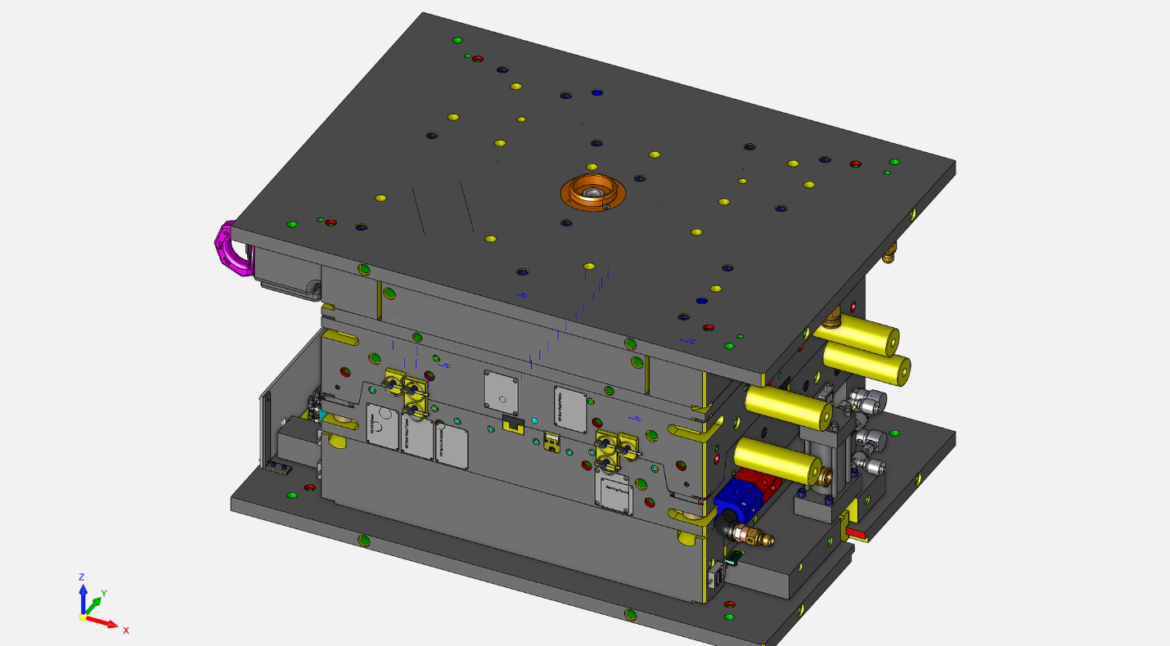

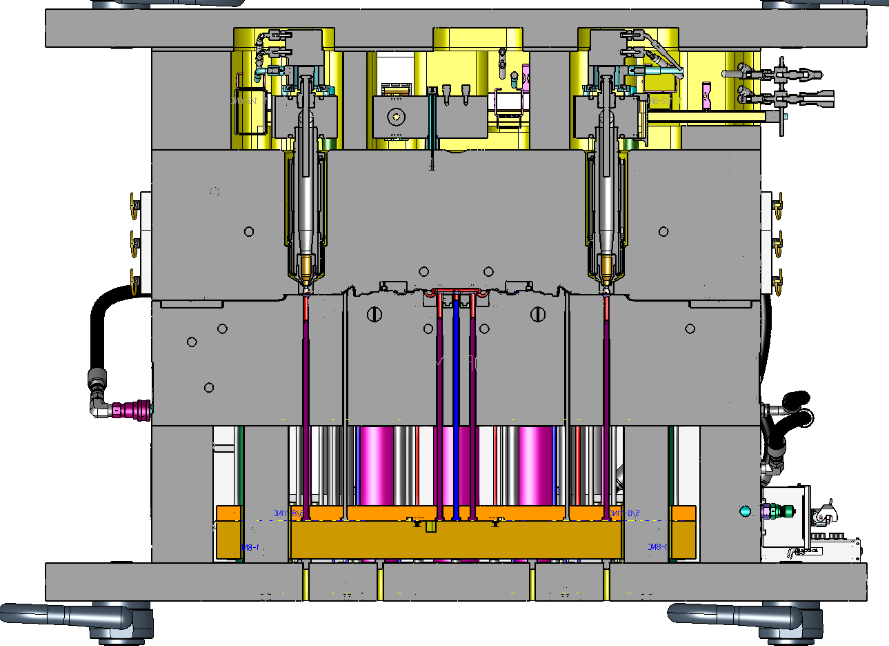

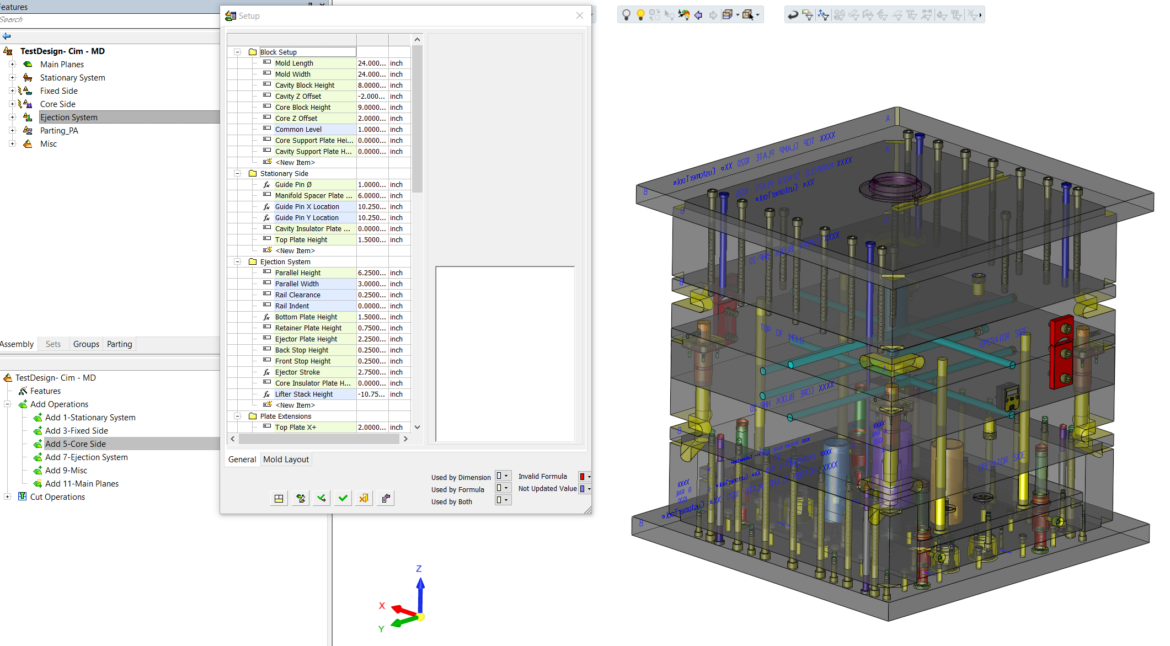

The world of plastic injection mold manufacturing has changed drastically over the last century. If you walked into a mold manufacturer today you would see various machines and computers run by complex programs. The 20th century has seen a lot of revolutionary technologies that have changed the way we manufacture molds,…

I was at a job fair in 2015, where I heard about the programs run through the Valiant Training & Development Centre. They would interview you and if you got approved for the program you were placed with a company that would pay for your training. I think that program…

The Circle 5 family welcomed students from high schools across Windsor and Essex County on October 6th as a part of Manufacturing Day. Organized by Invest WindsorEssex, Workforce WindsorEssex, and CAMM (Canadian Association of Moldmakers), Manufacturing Day is an initiative that strives to raise awareness of the skilled trades as…

On August 19, 2023 Circle 5 staff, family, and friends went to Rochester Place Golf Club for the annual golf tournament and dinner party. It was the perfect golf weather and there was an excited buzz in the air as everyone gathered for the shotgun start. Someone brought water guns…

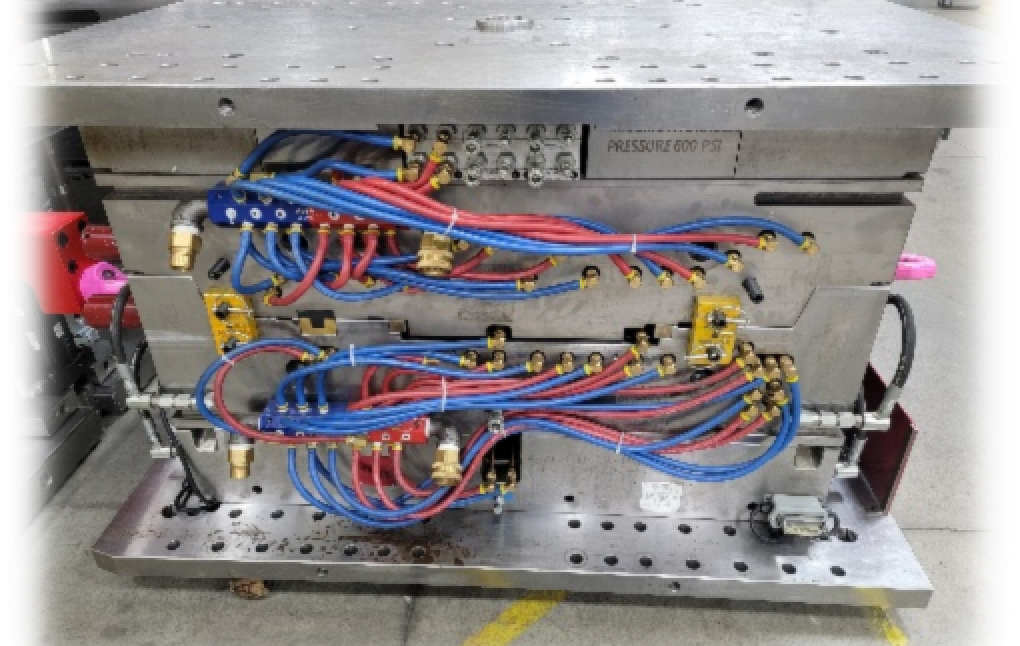

Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. However, it’s crucial to optimize injection mold production to ensure cost-effectiveness without compromising on quality. In this blog post, we will share seven valuable tips to help you achieve cost-effective injection mold production.…

Injection mold manufacturing plays a pivotal role in producing high-quality plastic components for various industries. While the focus is often on the final plastic pieces, it is equally important to emphasize the significance of quality control in the manufacturing process of the injection mold itself. By ensuring the precision and…

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity to create a part. The mold is a critical component of the process, as it determines the shape, size, and features of the finished product. In this post, we’ll take a closer look at…

So, you looked over our website, or maybe you know someone in advanced manufacturing, or maybe you did a tour of our facility. Regardless, you’ve done some research and you’ve decided you really want to join our team. Where do you start? Good news: there are several different ways you…

Parametric modeling is a CAD/CAM modeling approach that allows the creation of 3D models based on a set of parameters or dimensions. It involves the use of relationships between different elements of a model, such as dimensions, angles, and shapes, to define the model’s design and behavior. In parametric modeling,…

When my father and 4 others of his friends decided to start a new mold making company, they came up with the name Circle 5 given that there were 5 equal partners. They had to come up with a logo that expressed that. I remember seeing sketches of the logo…

At Circle 5 one of our core values is that we are family, and we live by that every day. People care about their families; they wouldn’t steer a family member wrong. So, it means so much to us when our employees recommend our company as a good place to…

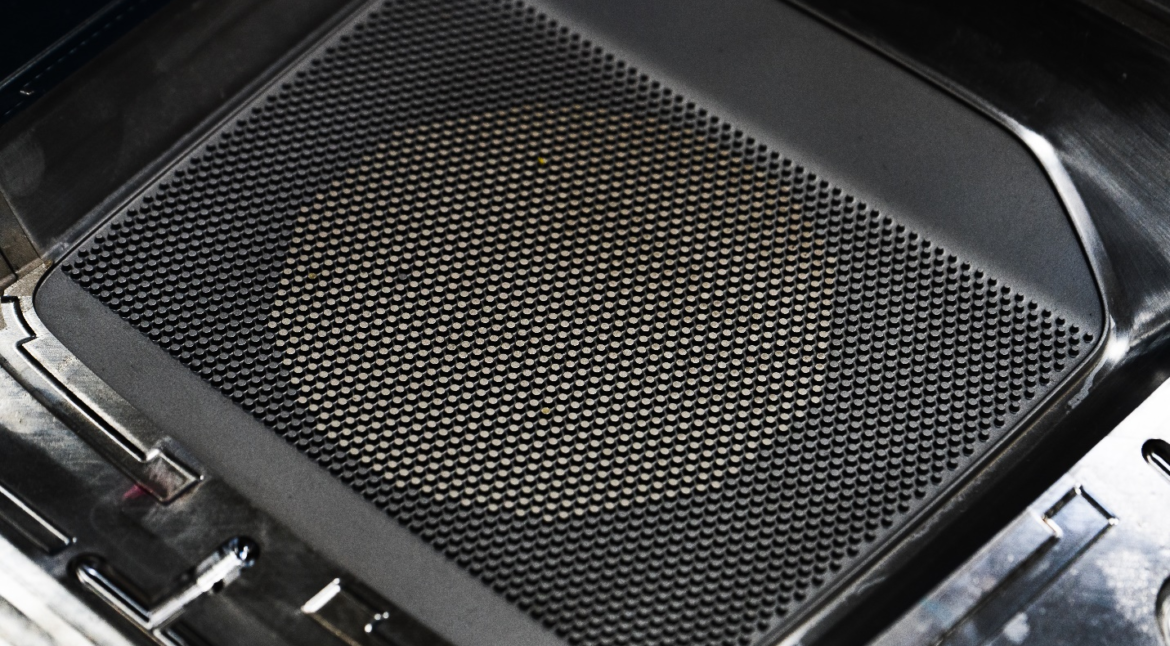

EDM (Electrical Discharge Machining) is a non-traditional machining process that uses electrical discharges to remove material from a workpiece. EDM is a highly precise machining method and is commonly used for the production of complex parts, particularly in the aerospace, medical, and automotive industries. It is also used to create…

Even with advanced technology and automated machinery, hand polishing is still required for plastic injection molds to achieve the highest level of finish and quality. Here are a few reasons why hand polishing is still necessary: Quality and consistency: Hand polishing allows for precise and consistent results that may not…

Being a moldmaker requires a combination of technical skills, practical knowledge, and attention to detail. Here are some of the key skill sets that are required to be a good moldmaker: A good moldmaker should have excellent technical drawing and design skills. They should be able to read and interpret…